Focusing your business to improve productivity and quality

Continuous Improvement refers to the process of continually improving products, services, processes, and systems in order to increase efficiency, effectiveness, and overall performance. It involves a never-ending cycle of identifying areas for improvement, implementing changes, measuring the results, and then repeating the process again.

This approach is often associated with quality management and is widely adopted in organizations as a way to drive innovation, increase customer satisfaction, and stay ahead of the competition. It requires a culture of continuous learning, collaboration, and a willingness to change in order to achieve long-term success. We provide expert guidance and support to help business leaders and CI Champions identify areas for improvement, implement changes, and attain sustainable results

Continuous Improvement Services

We help organizations to identify the root causes of inefficiencies in order to apply the right solution to streamline processes, reduce waste, and increase productivity.

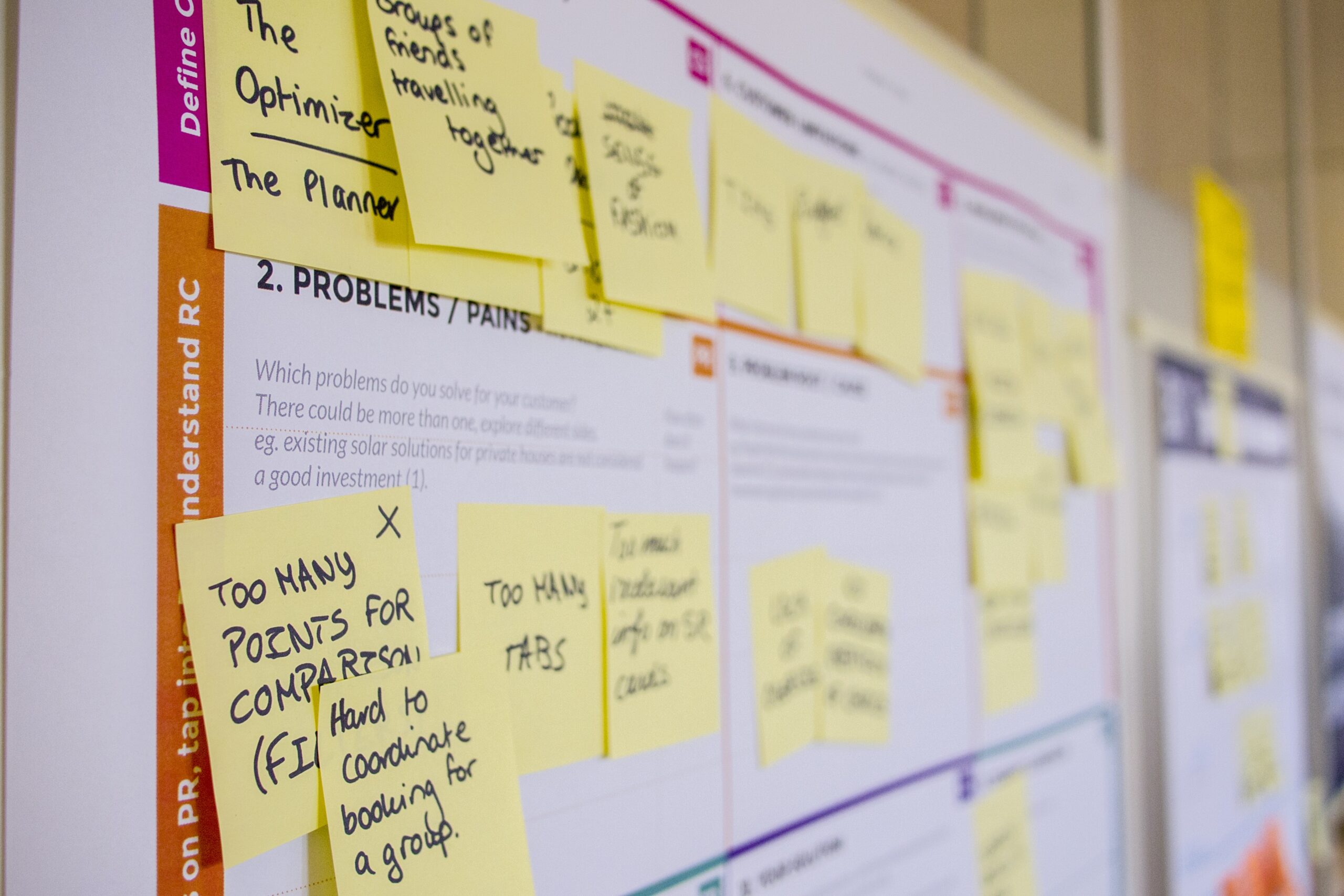

The success of a project or the adoption of new approaches depends on proper planning and effective communication with everyone impacted by the change. Leverage our experience guiding the mindset shifts, avoiding the pitfalls, and minimizing the disruptions that CI initiatives often require to achieve sustainable results.

Supporting organizations in creating a structure and culture that supports continuous improvement.

Helping organizations to establish and monitor key performance indicators and metrics to measure the impact of improvements.

Related Professional Development Opportunities

Whether you want to take a single class, receive an industry-recognized credential, or bring onsite training to your team, we can help you find instructor-led and online options tailored to your business’s specific needs.

If you have questions about these courses, please contact Andrew Lane.