MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

From paying for labor and raw materials to keeping up with energy and overhead bills, running a business can often feel like a daily juggling act of trying to balance manufacturing costs and profits. Of course, while opening up new markets, producing high-quality products and keeping your clients pleased are some of the primary road signs that your business is headed in the right direction, reducing company-wide costs is never a bad idea to help ensure your overall business and profit margins remain healthy.

At MANTEC, we’ve been helping manufacturing businesses in South Central Pennsylvania find and identify areas to achieve cost savings and increased productivity since our establishment as a private, non-profit 501 (c) 3 in 1988. Thanks to our expertise in consulting for the manufacturing sector, we often see the same areas where companies can reduce costs without it having a detrimental impact on their products or their ability to conduct business. The following ideas are some of the most widely applicable cost-saving techniques we regularly advise companies to consider.

1. Start With a Current Assessment

While a thorough assessment that includes a current look at all components that make up your business might not sound like a cost-saving idea, it’s actually the cornerstone for future savings. Without valid benchmarks for where your business currently stands, you can wind up making changes merely for the sake of shaking things up. On the other hand, when you’re armed with a current assessment of all aspects of your business, every change you make can be measured against valid data that helps you establish KPIs supporting real savings and productivity.

2. Increase Labor Efficiency

Since merely reducing how much you pay your employees is never a good route to saving on labor costs, think instead about how you can motivate them to work smarter. Some popular ways of encouraging efficiency are to inform your staff about methods such as LEAN Manufacturing, Six Sigma and other operational excellence techniques that can drive down your costs per unit produced. Plus, you can easily incentivize your workforce by rewarding employees who introduce new techniques that result in further time and cost savings.

3. Save on Costs Related to Materials

It can be beneficial to take a good hard look at how much you’re paying for everything from raw materials to office supplies. Especially with deals opening up daily online, you can often compare and negotiate these costs down with your current suppliers and distributors — who will be eager to keep you as a client and can often suggest other ways you might not be aware of to further reduce your materials costs.

4. Review Overhead Expenses

From utility audit solutions to how you utilize your warehouse space, you can potentially every cost you incur as a result of your overhead expenses when you look at each with a fresh focus. A utility audit can reveal areas of waste as well as give you a better understanding of how you’re currently purchasing your energy. Moving forward, a better deal with your energy provider, as well as a better usage of your facility, might easily result in ongoing savings.

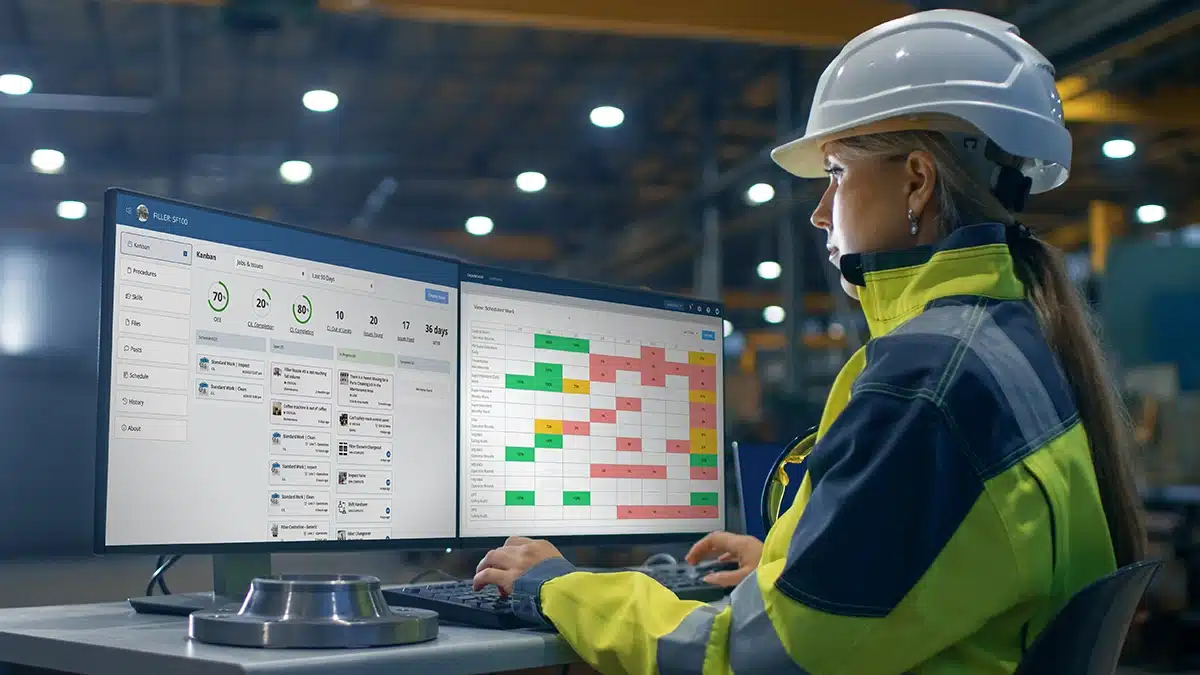

5. Research Capital Investments

While spending some money might not sound like a way to save, investing in manufacturing intelligence solutions often has a good return on investment. The smart technology and connectedness associated with Industry 4.0 offer significant potential for savings. Granted, it takes a certain amount of manufacturing planning, but with MANTEC’s help, you can get a good idea of what the transformation to a smart factory involves.

For more cost-saving ideas and further information on any of MANTEC’s services, contact us today.