MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

Many small and medium-sized manufacturers still use spreadsheets and manual tracking to manage their business. They know automated systems exist, but they have prioritized other needs since their current processes get the job done. But the pandemic has disrupted the entire industry, and manufacturers are scrambling for ways to increase their productivity. To further complicate the issue, many manufacturers find themselves in the lurch as key people depart — taking with them years of experience and critical institutional knowledge.

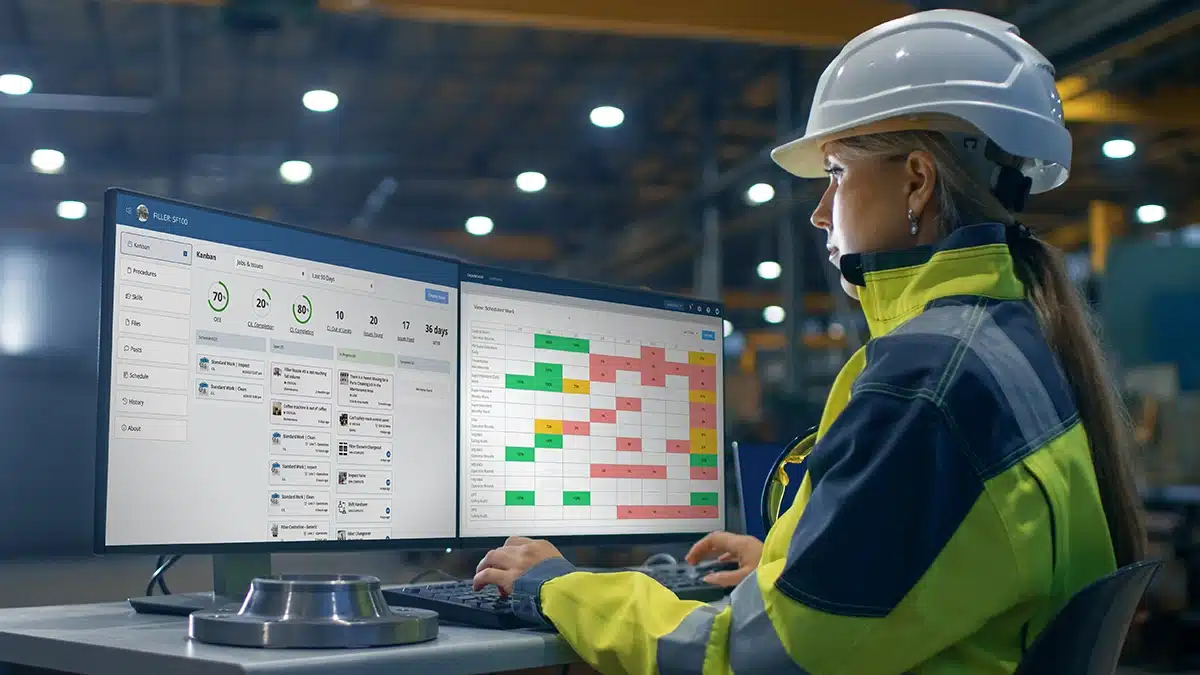

Enterprise resource planning (ERP) systems offer measurable benefits to manufacturers when correctly selected and implemented. ERPs integrate business processes so manufacturers become more efficient and flexible at managing resources. The technology automates many manual and routine tasks, which allows manufacturers to create smarter workflows and dedicate resources to higher-value tasks.

ERPs have a reputation of being expensive tools for big companies. But ERPs have evolved to become viable options for many small manufacturers to help ease the pain of supply chain disruptions and workforce challenges.

A small manufacturer may be ready for an ERP if they are:

- Growing: There are many direct and indirect impacts and details to manage.

- Having issues with operations: Centralizing data collection will streamline paths to improvement.

- Dealing with a merger or acquisitions: You seek alignment in many areas.

- Relying on legacy systems: It’s time to automate manual processes and break down silos.

ERPs Will Help With Delivery Time, Managing Costs and Improving Quality

ERPs can help manufacturers run more smoothly by integrating and streamlining processes leading to improved on-time delivery rates, which is key to customer satisfaction. ERPs can positively impact every department in a company, especially in these three ways:

1. Improve lead times and on-time delivery

An ERP helps a manufacturer implement a disciplined, data-driven process for the difficult challenge of estimating work completion. It has not been unusual in the current environment for a small manufacturer to have a 20-30 percent accuracy rate for hitting its delivery targets. Anything below a 50 percent accuracy rate for delivery time may not be sustainable in the long run. An ERP will help SMMs upstream and downstream, which will streamline the shipping process.

2. Manage costs

ERPs provide visibility into transactions and milestones. For example, “job costing,” compiling the direct and indirect costs related to a task, does not need to be done by estimation. With an ERP, a manufacturer can document specific expenses, such as labor, materials and overhead, to arrive at a more accurate number.

3. Improve quality

ERPs collect, store and link data. They provide a real-time record of how products are built, which may vary from how they were designed to be built. This increased visibility of real-time information can help manufacturers identify problems with incoming parts and materials.

ERPs Increase Visibility

A properly implemented ERP system functions as a single source of truth for a manufacturer. It ties together a multitude of business processes and allows the flow of information among those systems. It provides data integrity.

It is not unusual for a small manufacturer to have many disjointed systems. Accounting might be done on a small business software that is not connected to its procurement system or inventory controls. The production schedule might be entirely manual, possibly using an elaborate homemade system with only one or two key staff members having the institutional knowledge on how it works. An ERP brings standardization and centralizes processes and procedures.

One way for a manufacturer to consider digitizing its manual data collection is that every clipboard and spreadsheet is an opportunity for efficiency. For example, a small manufacturer was basing the valuation of its inventory on a semi-annual physical audit. With an ERP, inventory is managed on a real-time basis.

The reality is that many small manufacturers still lack the ability to automatically capture shop floor data. Instead, every morning they spend time sorting out what has been done on previous shifts and how to incorporate changes to do the work at hand.

Workplace Culture is Key to a Successful ERP Implementation

Workplace culture is key to a successful ERP implementation. High-engagement cultures tend to build a sense of capability and ownership in employees. It is similar to the “continuous improvement” mindset in which employees feel empowered to question the status quo and understand how incremental improvements impact the bigger picture. Employees must feel safe in suggesting changes.

Successful ERP implementations depend on:

- Leadership commitment: Owners or executives must support the changes necessary to break from the old ways.

- Management involvement: As with any technology adoption, communication is key. This is especially important as ERPs impact everything from an initial quote to collecting cash.

- Internal champions: When in doubt, someone must be deeply immersed in the project and able to act as a support resource.

- Communal ownership: Buy-in is essential as everyone will potentially gain something from an ERP implementation.

Another important aspect of an ERP implementation is being able to do an honest assessment of current processes, especially identifying product pain points. There is no reason to automate inefficient processes. Is there documentation of processes and standard work? You also must be able to document milestones and establish measurements.

An ERP implementation is a long-term play. Start with a phased implementation that addresses the biggest pain point (such as production scheduling, meeting material requirements, or inventory management). On average, ERP implementations can run six to nine months. It can take a full year or longer to implement an ERP system if the internal implementation team struggles to maintain forward momentum due to lack of support from management.

Make a Realistic Transition Based On Competency, Not Timelines

Many ERP implementations have failed because of unrealistic timelines and expectations and not being able to break from the old way of doing things. An early goal of an implementation should be for a company to “go live” with all of the basic functions of an ERP system, not meet an impossible deadline or unrealistic expectations that will deflate the staff.

Another common failure is running dual systems – trying to maintain old processes while implementing new ones. In essence, that is asking the staff to do twice the work. A manufacturer in that scenario will never let go of the legacy system.

A transition might look like this: In phase 1 of the implementation, the work order/production traveler is printed out with an additional bar code that is scanned in by the operator at each work cell. (The work order/production traveler is printed instructions, material, routings, and time allotted for how a job travels through work cells in the production process.) In phase 2, operators transition to scanning bar codes instead of passing along a paper job packet. When the staff is comfortable with the new process, the manufacturer replaces the printed job packet with electronic job packets that can be accessed by computers, tablets, smartphones, etc.

Future phases could include Radio-Frequency Identification (RFID) for tracking work in progress (WIP) and inventory management. RFID tags can monitor the movement of WIP and develop a record that may be useful in root cause analysis in case of damage or manufacturing flaws.

Your Local MEP Center Can Help You Learn About ERPs

ERPs present large-scale opportunities through incremental changes for manufacturers that are looking for ways to streamline and improve their processes. An ERP could be the right platform for small manufacturers to offset the loss of institutional knowledge and improve retention.

Experts at your local MEP Center are available to provide objective, unbiased assistance about ERPs.

About the authors

Bruce Newell

President and CEO, MANTEC

Scott Sipe

Chief Financial Officer, MANTEC

Chief Financial Officer, MANTEC

MANTEC is the Industrial Resource Center of South Central Pennsylvania and is part of the MEP National Network. Newell has extensive private sector experience in finance and manufacturing. Sipe is responsible for oversight of the organization’s finances, grants and contracts and the corporate information systems. He also delivers information technology planning and consulting services to the manufacturers in the region.

Story originally posted to Industry Week Magazine