MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

With the Internet of Things taking the consumer technology by storm, its factory-oriented counterpart, the Industrial Internet of Things, or IIoT, is spurring on a new revolution in manufacturing. The innovation has so much potential that some experts are calling it Industry 4.0. Despite its usefulness, some businesses are hesitant to adopt the IIoT for themselves.

According to a recent survey by the ARC Advisory Group, the majority of businesses fall into the pre-software category. Their study reveals that 27% of respondents, by far the majority, are currently “evaluating the potential of IIoT.” Another 19% are monitoring developments in the IIoT world, and 17% aren’t even sure what the IIoT is in the first place.

Phase 2: Semi-Connected Framework

Some companies have already identified their IT needs and installed the appropriate software. Others already have a pre-existing framework of software to use. For full-scale IIoT integration, however, all of your systems need to be interconnected for maximum efficiency.

The Industrial IoT Survey 2017 provides further insight into companies that comprise this category. According to their survey, 64% of respondents are “either engaged in or planning an IIoT project” within the next year. These companies have already formulated a plan for IoT adoption and are moving forward with their own, individual timelines.

Phase 3: Connected Infrastructure

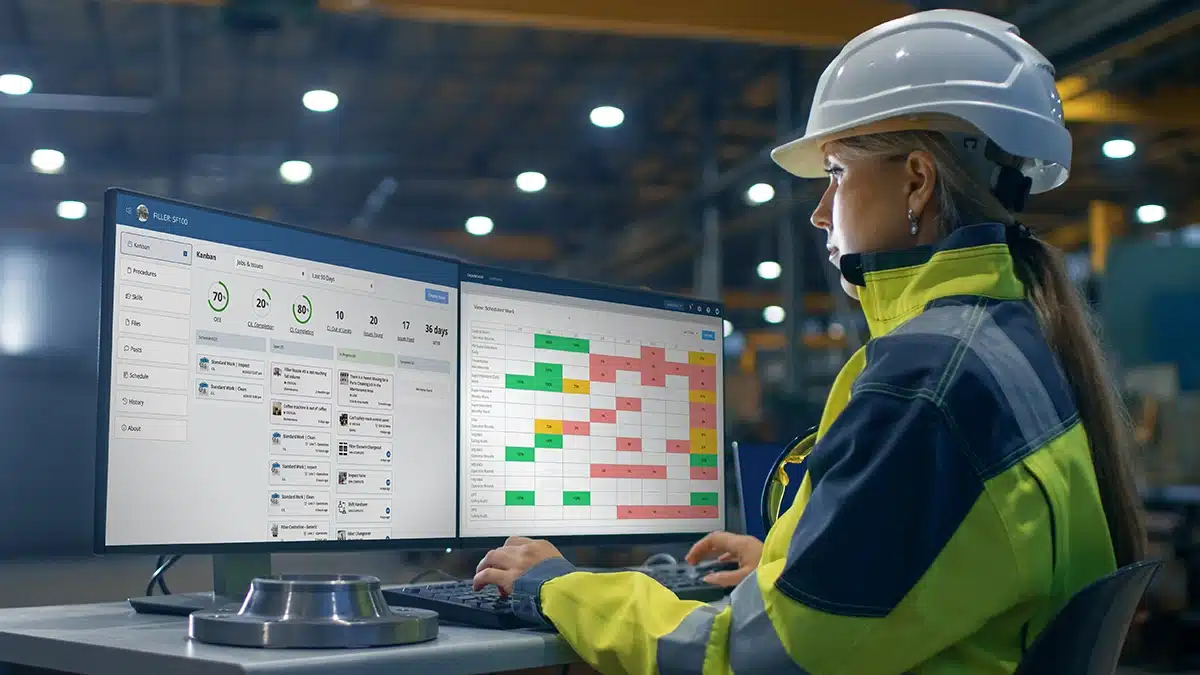

Factories that already have a fully connected system in place fall into this category. Sometimes referred to as the discipline of manufacturing operations management (MOM) or an infrastructure known as a manufacturing execution system (MES), these platforms are specifically designed to handle the ever-increasing data sets and data storage needs of the industry as a whole.

They’re also meant to provide a centralized system that is accessible by anybody – or any machine – with their appropriate permissions. Such accessibility isn’t without its pitfalls. The IIoT does require advanced cybersecurity and data protection.

Phase 4: Securely Connected System

A securely connected system is one that includes all of the different components of the IIoT. Software capabilities, communication between machines, accessibility and next-gen security are all required to enter the fourth and final phase of IIoT adoption.

Cybersecurity consists of numerous protocols and features that protect your entire system from cyberattacks. While experts agree that no system is fully exempt from the risk of an outside attack, significant advances in digital encryption, user authentication and data storage make today’s IT infrastructure more secure than ever before.

Some of the world’s top brands, many of which are headquartered in the United States, fall into this category. Names include Microsoft, IBM, Intel, General Motors, Cisco, SAP, Lockheed Martin, Gartner, Stanley Black and Decker and more. Recognized as true leaders in the IIoT, these manufacturers are paving the way for smaller companies and brands that want to follow in their footsteps.

Preparing for the Future of Manufacturing and IIoT Integration

The IIoT isn’t just a conceptualized vision of the future; it’s happening right now. While the technology is still in its infancy, manufacturers who embrace the platform will see improved productivity, increased efficiency and greater competitiveness within the industry. Although there will always be those who are opposed to change, especially in the workplace, this is one innovation that is definitely worth the risk.

Original article: https://www.iotevolutionworld.com/iiot/articles/434037-understanding-stages-iiot-adoption.htm

By Special Guest

Megan Ray Nichols, Correspondent

Megan Ray Nichols, Correspondent

Edited by Ken Briodagh