MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

The Internet of Things — or IoT — is a buzzword used frequently in everything from white papers and case studies to articles and blogs. But what exactly is the Internet of Things, and what is it doing for manufacturing?

What Is the Internet of Things?

The Internet of Things refers to the ever-expanding network of physical devices connected to the Internet. These devices gather and share data, resulting in an always-growing repository of data on everything from home thermostat settings and consumers’ purchasing habits to the location of vehicles and the condition of equipment. The result is a vast network of devices that can function independently of human action.

Thanks to the proliferation of wireless networks and affordable processors, manufacturers can make virtually anything a part of the Internet of Things. Drug manufacturers are starting to put tracking devices into pills to ensure patients are actually taking them. There are smart refrigerators that monitor products and alert you when it’s time to go grocery shopping. And logistics providers can track the location of every connected vehicle in their fleet at any point in time.

How Does the Internet of Things Pertain to Manufacturing?

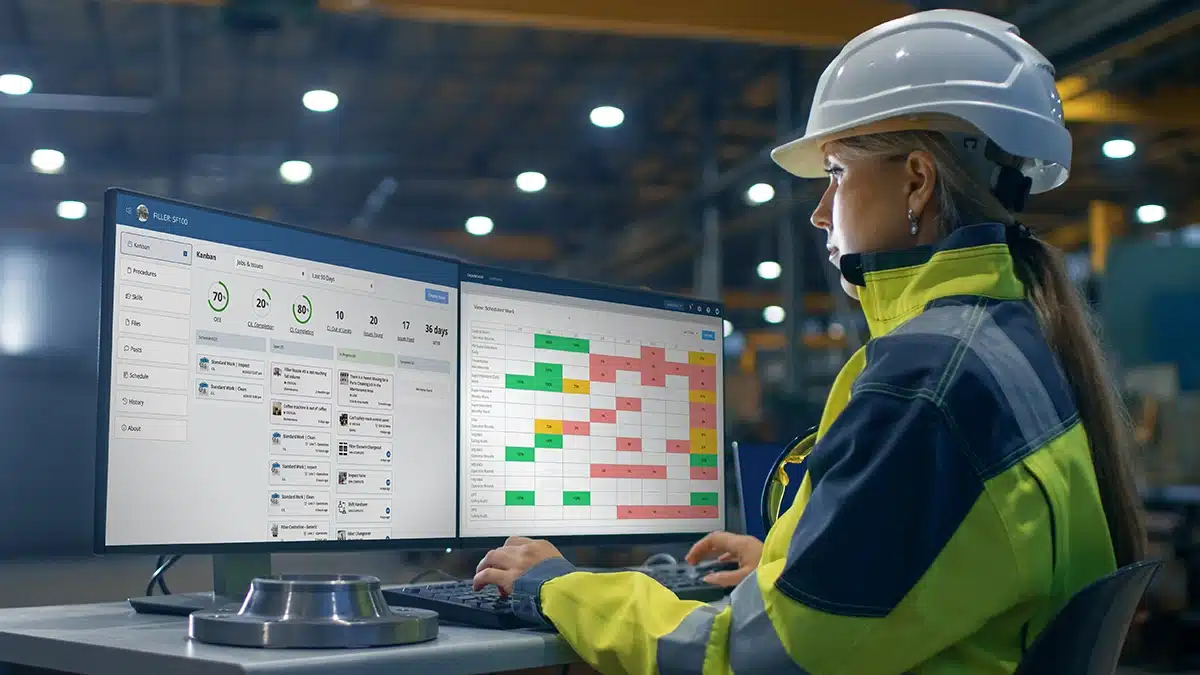

The Internet of Things plays an integral role in the drive toward smart manufacturing — or the ability for all data regarding the production process to be available at all times throughout the supply chain and product lifecycle. Because of this, the IoT is facilitating the digital transformation of manufacturing that allows businesses and enterprises to operate more efficiently.

So it’s not surprising that, according to experts, the manufacturing industry accounted for $178 billion of IoT spending in 2016. What’s more, manufacturing is expected to remain the biggest spender on IoT through 2020.

In addition to efficiency, the Internet of Things offers manufacturers many other benefits. It facilitates automation and makes data from the production process readily available. Moreover, it enhances customer-centricity because it makes it easier to incorporate user feedback.

To know how to effectively leverage the Internet of Things, it’s helpful to look at the primary IoT manufacturing use case. Globally, enterprises leverage the Internet of Things first and foremost for manufacturing operations, spending an astounding $102.5 billion on IoT in this area in 2016.

Using data generated by smart machines, manufacturers can determine how to reconfigure assembly lines to make them more efficient. Similarly, smart sensors embedded in equipment can assess its wear and tear and send notifications to maintenance when it’s time to repair or replace parts. These types of technological advancements can result in reduced waste, longer machine life, reduced labor, improved safety and, ultimately, an improved bottom line.

IoT Manufacturing for Small to Medium-Sized Enterprises (SMEs)

When it comes to the Internet of Things for manufacturing SMEs, it’s important to note that, until recently, implementing all of the modernizations to bring a factory online was an expensive proposition — one that could easily run into the millions of dollars. After all, it involves replacing or updating equipment so that all systems are outfitted with the sensors and processors needed to collect, transmit and share large amounts of data via newly installed infrastructure.

Recently, however, a new company called Dattus developed a way for small to medium-sized enterprises to turn their facilities into smart factories in a fraction of the time and at a much lower cost than conventional methods. Dattus provides small black boxes that manufacturers can install on their machines. These black boxes quickly collect, visualize and analyze data from a wide range of sources, providing manufacturers with the insights they need to make process improvements.

This invention effectively brings the implementation of the IoT well within reach of small to medium-sized manufacturers who don’t have the financial resources to make a large investment — but who nevertheless want to benefit from the advantages the Internet of Things offers.

MANTEC Can Help With Implementing the Internet of Things

Investing in technology to leverage the Internet of Things isn’t something you should undertake lightly. There are various use cases for the IoT, and determining which one or ones will best benefit your SME can be challenging. In addition, it can be difficult to find the right provider with the know-how to effectively integrate IoT technology into your existing operations.

For this reason, you’re best advised to work with an experienced consultant like MANTEC who understands the manufacturing needs of small to medium-sized enterprises in South Central Pennsylvania. We’re a private, non-profit 501 (c) 3, and we’ve been serving the needs of our clients for more than 30 years. In addition, we’re experts in the technological advancements that can help today’s manufacturers become more responsive, agile and profitable.

To learn how to leverage the Internet of Things to your — and your customers’ — advantage, contact us today.