MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

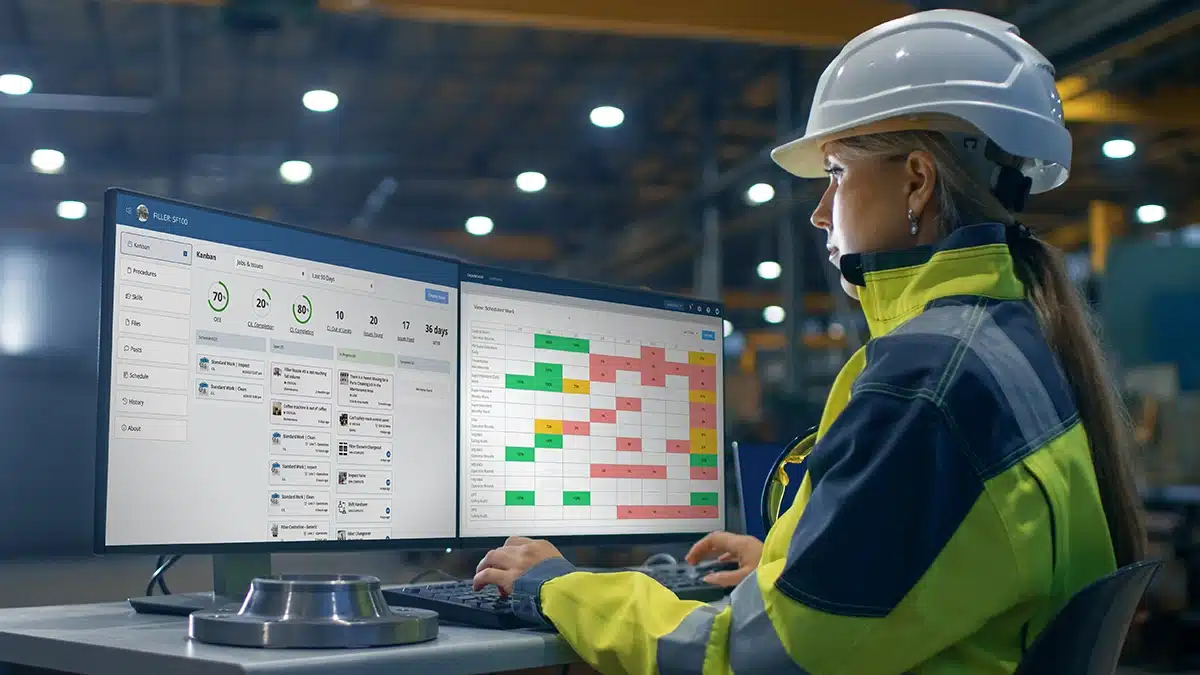

While some people think of manufacturing as the mechanical process of producing goods and services with machinery, equipment, and manpower, those who work in the industry understand that it is much more involved. Data collection is a key component of the modern manufacturing process that helps companies monitor and control costs and ensures the smooth operation of the plant.

More Manufacturing Technology Resources

What Are the Benefits of a Data-Driven Manufacturing Environment?

Why has data collection for manufacturing become so important? Access to real-time data helps operations managers view, analyze and act upon time-sensitive information with greater speed and accuracy, making the manufacturer more responsive to customer needs.

For example, reliable data collection practices can ensure that managers have access to up-to-date inventory levels that can prevent an out-of-stock situation that can lead to delayed shipments and customer dissatisfaction. Other benefits of efficient real-time data collection practices include:

- Easier management of multiple job tasks – Today’s manufacturing managers must juggle multiple jobs and tasks at once. A sound data collection process features a fully integrated software system that provides timely, accurate data that will increase productivity and give managers the flexibility to make immediate adjustments to job time allocations when needed.

- Generating more accurate reporting data – Data collection for manufacturing gives managers access to timely, accurate reports that detail work progress by worker, project, work area or supervisor. Managers can also more easily track workpieces as they travel through the shop for enhanced inventory management and improved quality control.

- Better control of labor costs – Labor is one of the largest costs for manufacturing entities. An efficient data collection methodology gives managers real-time access to information regarding payroll, labor costs by shift, department or project, and when employees are logging on and off to work orders. Supervisors can determine where labor shortages or an over-allocation of manpower resources may be occurring and make the necessary changes.

- Reduction in errors – Manual data collection processes introduce the possibility of human error, which can provide inaccurate information that inhibits the decision-making process. Real-time data collection automates the process and eliminates mistakes resulting from illegible handwriting and multitasking workers who are in a hurry.

- Increased customer responsiveness – Real-time data collection processes can make manufacturers more adaptive to the needs of their customers. For example, the manufacturer can easily change the priority of an order to satisfy a customer request and respond more quickly to inquiries.

Improving Data Collection on Your Factory Floor

The biggest challenge that many manufacturers face is the inefficiency of the data collection process at the point of entry. Some manufacturers implement sophisticated computer systems and software packages to facilitate data analysis, only to discover this method fails due to inaccurate data. As the saying goes, “garbage in, garbage out.”

In addition, many of these systems are not suitable for use on the shop floor. Consequently, the terminals must be placed in an office that may be located far from the floor, which significantly slows the data entry process and requires the staff to spend more time away from their regular work activities. Too often, this results in an inaccurate, inefficient data collection process and a drop in productivity.

Manufacturers throughout Pennsylvania are discovering the advantages of implementing a touch screen data collection system that can be used on the shop floor. This enables the manufacturer to place the data collection unit exactly where it is needed and where it will provide the maximum value.

A standalone touchscreen data collection system is fast and easy to install and requires little staff training, which saves time and money and minimizes disruptions to your normal operating processes. The touchscreen eliminates the need for a keyboard, which makes it a user-friendly solution for staff members.

Knowing How to Process the Collected Data

Collecting data faster and more accurately is only half the battle — you also have to know how to process it efficiently. With the reams of data that manufacturers have access to these days, this can pose quite a challenge. Many small and medium-sized manufacturers may not have the expertise and resources to accomplish the task.

MANTEC Can Assist With Your Data Collection and Processing Needs

MANTEC is a York, PA-based nonprofit manufacturing consulting firm that understands the challenges that South Central Pennsylvania manufacturers face. Our experienced staff possesses a comprehensive knowledge of the process of data collection for manufacturing and how it impacts your business. We’ll collaborate with you to formulate a plan for the more efficient collection and processing of data in your plant so you can maximize its benefits. We have the expertise and resources to resolve your most difficult data collection issues.

Give us a call at 717-843-5054 to learn more about how more efficient data collection and processing practices can benefit your manufacturing operation.