MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

While the concept of operational excellence is difficult to define, its attainment is vital to any manufacturing organization that wants to stay relevant in today’s highly competitive business climate. A focus on continuous improvement is usually what separates the companies that achieve operational excellence from those that fall by the wayside.

This commitment to continuous improvement must come from every employee — workers must feel empowered to intervene when they see a potential obstacle in the “flow of value” between the company and the customer.

Attaining Operational Excellence Through Employee Engagement

Many manufacturing experts agree that having an engaged workforce is perhaps the most important factor for reaching operational excellence. Employees who are engaged in their work and the company tend to work faster and more efficiently and are more likely to make serving the customer a top priority. Leadership can facilitate employee engagement by demonstrating a commitment to accountability, patience, an openness to receiving employee input, incentivization and mentorship.

Specific steps for increasing employee engagement include:

- Developing a clear business strategy – Having a well-developed manufacturing strategy that supports the overall corporate strategy creates a clear vision and provides guidance for employees in their daily activities.

- Creating goals – The strategy should be broken down into specific goals for each work area. Goal-setting gives employees a stake in the outcome of the manufacturing operation.

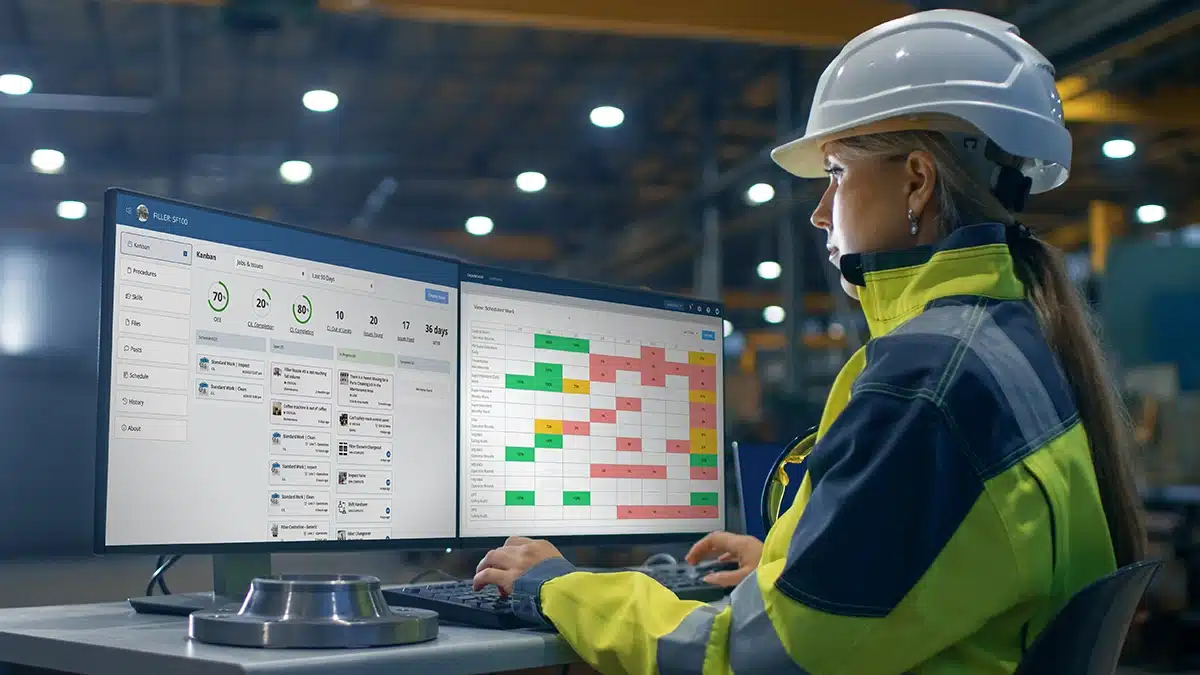

- Developing KPIs – Key performance indicators provide a method of measuring the progress toward achieving the goals. Employees will always know where they stand and what actions they need to take to remain on track or improve their performance.

- Developing clear-cut KPI communication methods – It’s also important to support the KPIs by developing and implementing effective strategies for communicating them to employees in a timely, efficient fashion.

- Determining a reliable process for KPI interaction – All members of the organization, from top management to shop floor employees, must have access to a process for acting upon KPI-related information.

- Aligning incentives with goal achievement – Offering incentives is a strong motivational tool for promoting employee engagement. To ensure incentivization achieves the desired result, the rewards must be aligned with the achievement of goals.

Following these steps will encourage employees to take ownership of their work and make them feel that their contributions are highly valued. You should notice an increase in productivity and a more positive attitude that permeates your entire workforce. Ultimately, this will lead to the sustained continuous improvement that every manufacturing organization needs to attain operational excellence.

MANTEC: Your Source for Cost-Effective Operational Excellence Training in PA

MANTEC offers a series of operational excellence training programs for small and medium-sized manufacturing companies in South Central PA. Our programs cover key topics such as Six Sigma and lean manufacturing that can increase your operating efficiency. We also offer training for operational excellence that can help your company attain valued ISO 9001 certification as well as on-site consulting.

In addition, MANTEC can provide customized solutions to meet your ever-changing needs by sending one of our industry experts is analyze your facility and manufacturing process and help you implement success-driven solutions.

For More information, contact MANTEC today or sign-up for one of our upcoming training!