MANTEC: Strengthening South Central Pennsylvania Manufacturing Every manufacturing operation has them: the skilled machinist promoted…

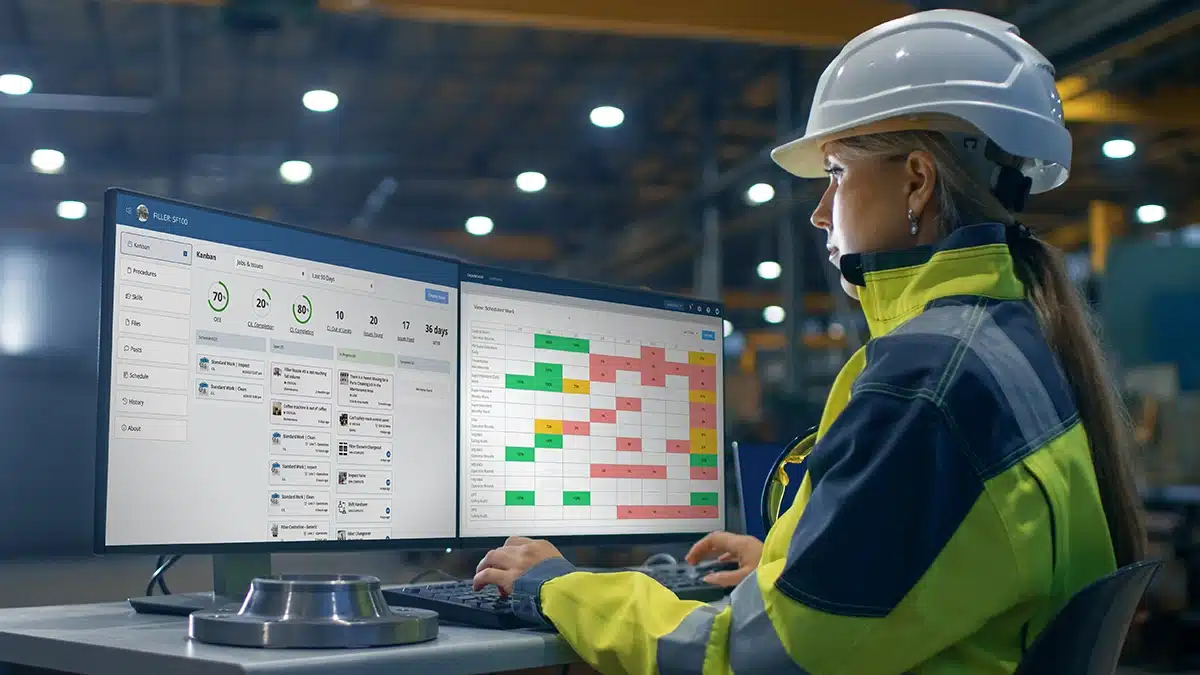

The term “big data” applies to large volumes of structured and unstructured datasets that, through analysis, can reveal specific trends and patterns. Big data analytics is now shaping the way organizations in virtually every industry process information, including manufacturing. Trying to harness all of this information can be a daunting task. The challenge that many manufacturing entities face is learning how to leverage data to develop a strategy for meeting their productivity and operational objectives.

More Manufacturing Technology Resources

Exploring the Benefits and Applications of Big Data in Manufacturing

Manufacturing companies of all types are learning how to leverage big data to improve various aspects of their operations. Examples of specific applications and their benefits include:

- Minimizing supply chain risk: Disruptions to the supply chain can have devastating consequences for any manufacturing operation. Big data analytics can lower the risk by providing information that can help companies identify and anticipate delays that could impact product shipments. It can also use cloud-based data to share information with supply partners and strengthen their relationships.

- Improving quality and efficiency: Access to big data can increase a manufacturer’s ability to use quality as a competitive advantage. Companies will have the power to seamlessly integrate quality with compliance, allowing them to take a predictive instead of a reactive approach to quality control. From an efficiency perspective, manufacturing operations will be able to utilize sensor-provided data from their equipment to reduce waste and make process improvements.

- Enhancing preventative maintenance practices: Equipment upkeep represents a major expense for most manufacturing operations. Companies can now invest in “smart” machines that provide access to predictive analytics. With this data, manufacturers can more accurately monitor the performance and health of their equipment. They can take more of a preemptive approach to preventative maintenance and detect minor issues to avoid more expensive problems.

- Being more responsive to customer preferences: Whether manufacturers make products for business or consumer use, big data analytics can provide additional information regarding what customers want and need. For example, companies that offer online tools that enable buyers to add custom features to a product can learn more about user preferences. They can then integrate this feedback into their future product development endeavors. Customers will recognize that the company is being responsive to their needs, which can increase brand loyalty.

- Optimizing production operations: These days, manufacturers must be able to respond quickly to market fluctuations and changes in the business climate. The availability of volumes of data allows companies to make faster, more informed decisions. They’ll be able to leverage their assets to make real-time adjustments to production capacity as needed, leading to optimal efficiency. This increased flexibility can also provide a competitive advantage in the marketplace.

MANTEC Can Help You Leverage Big Data Analytics in Manufacturing

If you’re a manufacturer in South Central PA, MANTEC can show you how to use the power of big data analytics to optimize your production and business operations. Call us at 717-843-5054 or contact us online to learn more.